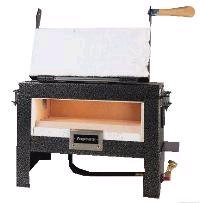

Forgemaster Large Powder Coated Gas Forge with Hood

Elevate your forging capabilities with the Forgemaster Large Powder Coated Gas Forge, designed for professionals who demand quality and versatility. This powerful forge features a spacious heating chamber measuring 13" wide x 11" deep x 3" high, providing ample space for large projects. The exterior dimensions are 22-1/2" wide x 19" deep x 14-3/4" high, while the hood measures 17" wide x 8" deep x 20-1/2" high, complete with a 5-3/4" round exhaust opening for efficient venting.

Why Choose Forgemaster™?

- Premium Construction: Built from thick 12 gauge (.109) hot rolled steel for durability and longevity.

- Heavy-Duty Design: Features a robust two-piece clamshell construction with a full 3" heat chamber opening.

- Precise Fuel Control: Needle valve fuel adjustment ensures accurate fuel flow distribution.

- Innovative Design: The unique slanted base allows easy access to the heat chamber, enhancing user convenience.

- Durable Finish: Coated with a tough, powder-coated black and silver “hammered metal” finish for added resilience.

- Extended Hose: Comes with a 9' long fuel hose, 12" longer than many other forges, for added flexibility.

- Ready to Use: Includes a fully assembled, UL listed regulator and pressure gauge, and a convenient spark igniter assembly.

- Heavy Cast Iron Burners: Permanently welded to the housing top for reliable performance.

- Easy Maintenance: Quick replacement of lining and hearth brick material ensures long-term usability.

- Customizable: Optional side ports can be added for an additional $105 per port, with customizable control and door handle placement.

This special order forge is shipped in 3 boxes and comes with standard dual controls. Enhance your forging setup with the Forgemaster Large Powder Coated Gas Forge, a reliable choice for serious blacksmiths and metalworkers.

Forgemaster FAQ

What size propane cylinder should I use?

In the summer months, the Forgemaster forging furnace will operate well on a 20# propane cylinder (the type used on most backyard barbeque grills) with a vapor valve. Propane boils at -44°. Forgemaster forging furnaces burn the vapor that is produced from that boil. Therefore, the closer the ambient temperature is to -44° the slower the vapor is created inside the cylinder. During periods of prolonged use in cold weather, you will consume the propane vapor faster than the evaporation rate and will need to employ a larger capacity cylinder (30-60 lb. cylinders).

What is the BTU of a Forgemaster?

BTU is a standard measurement of heat produced by a furnace. Each Forgemaster burner will produce about 50,000 BTU's when operated at 8 pounds of propane pressure. Compared to a normal household furnace (100,000 BTU's), this may seem modest. However, a two-burner Forgemaster produces approximately the same heat necessary to heat a 3-bedroom house but is confined to an area of about 2.5 cubic feet. For blacksmithing and farrier applications, a Forgemaster operating at welding pressure (12-14 psi) will produce in excess of 2500 degrees F.

What is the best way to mount the Forgemaster in my truck?

There are several ways to secure the Forgemaster for traveling. Some farriers bolt it to the truck bed, while others use a Swingmaster adjustable forge-mounting arm. Consider your vehicle and work style to choose the best method. Ensure the Forgemaster is convenient and secure, and keep it away from combustible materials after use. The SWINGMASTER is highly versatile, with nearly infinite position settings, a low profile, and easy adjustability. Built with 11 gauge steel and secured with 7/8" cold roll pins, it’s designed for tough applications and protected with a durable powder coating.

Does the Forgemaster operate on Natural gas?

Yes, but several requirements need to be met. The pressure for natural gas household appliances is lower than what is required for an atmospheric forge. A commercial gas pressure of 3-5 psi is needed to operate the Forgemaster on natural gas. Additionally, a different orifice is required. For more information, please contact Forgemaster at 1-636-528-4832.

Can you weld steel in a Forgemaster?

Yes, the Forgemaster can weld steel and aluminum. For step-by-step instructions on forge welding steel and aluminum, please visit Forgemaster Tips page.

How To Light the Forgemaster:

Lighting the Forgemaster TM

A general understanding of the properties of propane and a venturi will make lighting your forge a simple thing. It is important to know that propane has a relatively small ignition envelope. In order for propane to ignite it must be mixed with air in a ratio of 2% to 10% propane vapor and 90% to 98% air. Mixtures that vary from these limits will make ignition very difficult or impossible.

When the forge is cold, the Forgemaster TM venturi burner will draw air at a tremendous rate. Because of the draw of a cold forge, the fuel-air mixture will normally be outside the ignition limits of propane vapor. Forgemaster TM forges have an air limiter at the rear of one of the burners to restrict the amount of air that can be drawn into the venturi burner. Keep these three pieces of information in mind when you light the forge, and follow these lighting procedures:

- If your Forgemaster TM model is equipped with a front door, open the door fully during lighting, as shown below.

- Make certain that the brass fuel control valve on the forge is turned OFF.

- Open the valve on your propane tank.

- Set the regulator gauge to 10 psi (15 psi for the E-1 model). To set the regulator, slowly turn the center knob of the regulator clockwise until the needle on the gauge points to the number 10.

- At this point you should always test the tank, regulator, hose and valve for any loose fitting and propane leaks. This is easily done with a commercial gas leak checking liquid. You can make a sudsy liquid by placing a small amount of liquid dish detergent in a jar with some water and then apply the sudsy solution to every fitting and joint which is under propane pressure. If the solution continues to form bubbles you have a propane leak, and should shut the tank valve off and repair the leak BEFORE proceeding to light the forge. Even a small leak should be fixed immediately. When you are certain that there are no leaks in your forge system continue with step 6.

- Close the air limiter at the back of the venturi burner. (Some older models of Forgemaster TM are not equipped with the air limiter, but you can purchase one from you dealer). The purpose of an air limiter is to limit the amount of air that is drawn into the venturi burner. If you have an older model and have difficulty lighting it, you can make a temporary limiter out of sheet metal and place it over the air intake at the rear of the venturi burner during lighting. Make sure that you have a fairly tight a fit over the venturi burner.

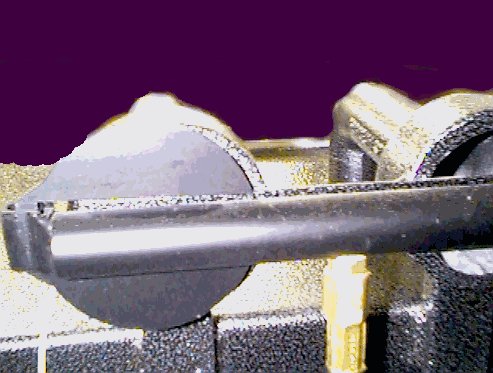

The photo below shows the air limiter in the proper position for lighting the forge.

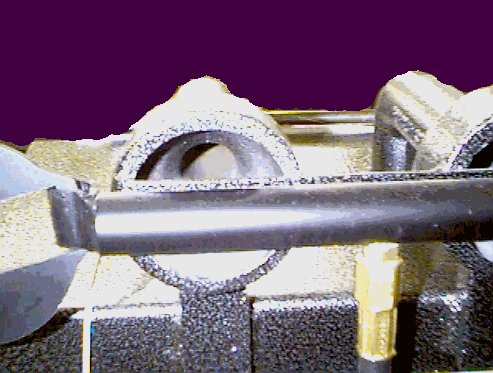

After the forge is properly lit you should open the air limiter as shown below.

- Be sure to open the front door if your forge is equipped with one.

- Stand to the side of the forge, away from the front opening. Open the brass fuel control valve at least one full revolution. Wait 2 seconds and then...

- Push the red button on the spark ignitor. You should not need to push the button more than 2 times if you have followed these steps.

- After the forge is properly lit you may close the front door if you forge is equipped with one, and begin forging.

When the forge is burning properly you will a flame in the heating chamber similar to either of those shown in the photo below. You will not be able to see the flames in bright sunlight, and you should NEVER get close to the front of the forge. Obviously forges are hot.

If the gas ignites prematurely, it will burn in the venturi burner. This will produce a loud, gurgling sound, and a blue flame can be seen inside the venturi burner. When viewing this from behind the forge, look into the venturi (from about 18" away). A forge running in this manner will not produce enough heat for forging steel. It will look like this -